Preview

KF2-A 3000-150-153-CJ

KF2 with Cooling Jacket (CJ ) for use with a liquid cooler unit.

Every time a KF2 controllable gas spring is stroked, energy is transferred from the press to the spring. The amount of energy transferred is a function of the spring force multiplied by its stroke length.

For applications where a larger number of KF2 springs operate at higher production rates, liquid cooler units are recommended. For applications where liquid cooling is required each KF2 gas spring is fitted with a cooling jacket, thus allowing efficient circulation of cooling liquid around each KF2 gas spring.

For applications where a larger number of KF2 springs operate at higher production rates, liquid cooler units are recommended. For applications where liquid cooling is required each KF2 gas spring is fitted with a cooling jacket, thus allowing efficient circulation of cooling liquid around each KF2 gas spring.

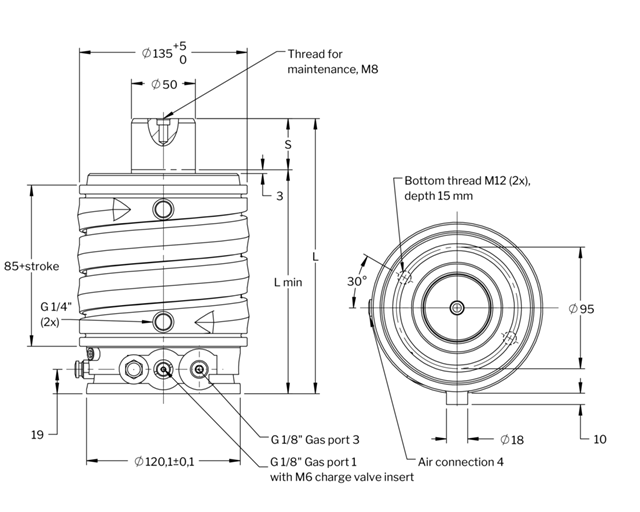

Diagram / specifications section

Preview

| L min | Minimum Length (in) | 11.5 |

| S | Stroke Length (in) | 6.02 |

| L | Total Length (in) | 17.52 |

Item specifications

- End Force At Full Stroke (LBF)9400

- Force Increase By Temperature Percent Per (°F)0.17

- Gas Volume (CuF)0.0423776

- Initial Force at max. pressure (lbf) 6744

- Max Charging Pressure (Psi)2175

- Max Piston Rod Velocity (FtMin)157.48

- Max. Operating Temperature (F)176

- Min Charging Pressure (PSI)362

- Min. Operating Temperature (F)32

- Recommended Max Strokes Per MinuteSee separate info.

- Weight (lb)35.464