Hot Stamping

Optimizing Hot Stamping Operations

Hot stamping, also known as press hardening or hot press forming, is a manufacturing process in industries like automotive, where lightweighting and high-strength components are required. This method allows the use of thinner, high-strength steel sheets, helping to reduce part weight while achieving variable strength levels within a single component—ideal for crash absorption and structural integrity.

The challenge of utilizing gas springs in hot stamping is the harsh environment- filled with heat, dust, and debris that can potentially affect gas springs functionality and service life.

Fortunately, KALLER has solutions to not only increase manufacturing up-time, but also improve part quality in hot stamping.

Optimize Hot Stamping Operations:

HDP- Increase Uptime & Service Life

HDP (Heavy Duty Protection) covers are a simple addition to gas springs that are used in harsh environments such as hot stamping- to reduce contamination, which in turn, provides a more reliabile throughput with less downtime & maintenance.

HDP's protection of gas springs help you:

- Minimizes downtime, maintenace costs, and gas spring replacements

- Increases production reliability and throughput

- Extends the life of gas springs in dirty environments

KF2- Reduce Splitting, Wrinkling, & Buckling

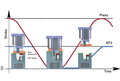

The KF2 Gas Springs are controllable springs, meaning the return stroke can be delayed so no force is applied when the die opens. With this delay to the stroke, the risk for splitting and damage to the produce part is decreased.

KF2 Advantages:

- Locking function for double-stage drawing or deep draw forming

- Improves part quality and reduces splits, buckles and wrinkles - during press ram return

- Can combine two forming operations into one tool- reducing the number of dies