Gas Springs for a More Sustainable Future

As a leader in Nitrogen Gas Spring Cylinders, we strive to reduce our environmental impact for a more sustainable future and have set environmental goals for 2025 in three main areas: energy, water, and waste.

We are Dedicated to Reducing our Impact

At KALLER, we believe in the ethical responsibility to take precautionary measures to protect the environment and are committed to reducing our impact. Based on scientific evidence indicating risk to our environment, we believe action is necessary. KALLER and its employees are dedicated to doing their part to reduce waste and protect the planet.

When you choose KALLER, you get high-quality Gas Springs and our commitment and efforts for a more sustainable future.

We are committed to making environmentally conscious decisions and actions to help reduce our impact and provide a more sustainable world. Since 2019, we have taken actions to reduce our impact on the environment and are almost to our goals.

Our Goals

|

|

|

Energy15% reduction by 2025 in scope 1 and 2 emissions |

Water20% reduction in water usage by 2025 |

Waste15% reduction in process waste by 2025 |

Our Latest Efforts

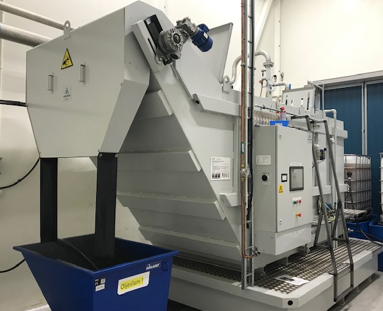

- Installed central cooling liquid equipment and evaporator

- Reduced cooling oil as waste by 95%

- Reduced transportation of used cooling oil waste by 90%

- Recycling of all steel (metal chips and parts from the production process)

- Recycling used Gas Springs (Contact Us on how to safely recycle Gas Springs)

- Installed sorting and recycling stations for various recyclable materials

- We reuse all our processed water from washing machines

- We have reached our waste reduction goal and are currently at a 20% reduction since 2019!

Central Cooling Liquid Equipment

Our goal for installing this was to reduce the usage of cooling liquid and water as well as improve the safety of the work environment by reducing contact with the cooling liquid. This eliminated the disposal and transportation of 70,000 liters of coolant liquid per year!