Simplify the EV Charge Port Cutting Process

The KALLER® Flex Cam allows you to increase the number of operations in a die and performs controlled, high-precision piercing and stamping — increasing production speed and reducing tool and die costs. Read our blog to learn more.

How the Flex Cam Works to Improve Your Process

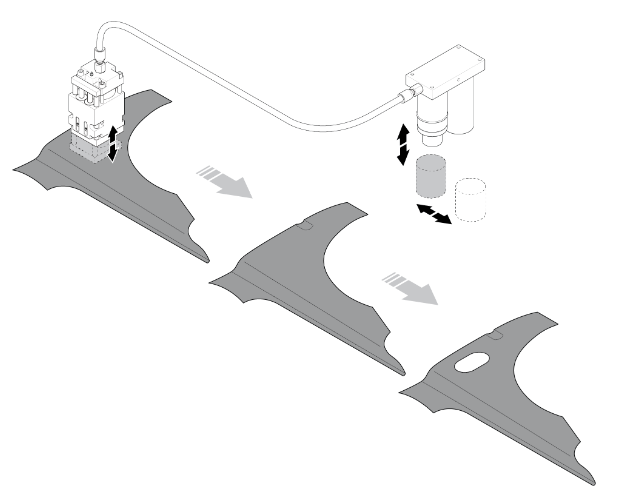

The multi-functional and high-precision KALLER Flex Cam cutting tool has become a standard component for many vehicle manufacturers. By using highly accurate guiding elements, without side deflections, the cutting process is simplified, and the number of dies required is reduced — cutting costs at the same time.

For new vehicle models, a new production process can be set up to include a charge port for EV models while eliminating ports on other models — all with the same die. This advanced, cost-effective cutting tool can be positioned at a 360° angle and will perform multiple operations in one die — allowing vehicle manufacturers to reduce the amount of steps and tools required for producing a fender with, or without, an EV charge port.

KALLER Flex Cam Features and Benefits

- Controlled force and safety features.

- Multifunctionality (several operations in one die).

- Reduced costs by minimizing number of dies needed.

- Durable and long-lasting.

- Space efficient.

- 360° application area.

- Able to punch upwards at negative angles.

Fast, Reliable Delivery Worldwide

Since 1983 we have developed and refined the gas spring technology, but we have been in the business since 1876 — for many years as a world leader, with an export share of 95%. We have locations for your distribution and service needs worldwide to support your spring component needs. Find your distributor or contact us today for your EV stamping force and motion control solutions.